Exploring Polyester Acrylate Mechanical Properties for Enhanced Global Applications

Polyester acrylates are pivotal in the energy-curing industry, offering versatile solutions for graphic arts, industrial coatings, adhesives, and 3D printing. A recent technical report from our laboratory provides in-depth analysis and characterization of various polyester acrylates in the Photomer® series to validate their mechanical properties . This report focuses on improving product understanding through rigorous testing and standardization.

Objectives and Methodology

The primary objective of this study was to evaluate the mechanical properties of different polyester acrylates and confirm their performance. Eleven formulations were tested: Photomer® 5429, PureOmer® 5450, Photomer® 5425, PureOmer® 5437, Photomer® 5442, PureOmer® 5443, Photomer® 5419, PureOmer® 5433, Photomer® 5439, and Photomer® 9145.

PureOmer® products are derived from renewable resources, emphasizing sustainability and environmental responsibility while maintaining high performance standards in energy-curing applications.

Key Findings

Tensile Properties

Tensile properties were assessed using a model 34SC-5 tabletop tester with a 5 kN load cell at a strain rate of 50 mm/min, adhering to ASTM D638 standards. Key parameters included tensile modulus, tensile strength, and elongation at break.

- Tensile Modulus and Strength: PureOmer® 5433 demonstrated the highest tensile modulus (1265 MPa) and tensile strength (40 MPa), highlighting its robust structural integrity. In contrast, PureOmer® 5437 exhibited minimal performance with a tensile modulus of 19 MPa and tensile strength of 1 MPa.

- Elongation at Break: Photomer® 9145 had the highest elongation at 21%, indicating excellent flexibility. Photomer® 5442 displayed only 1% elongation, reflecting its rigidity and brittleness.

Glass Transition (Tg)

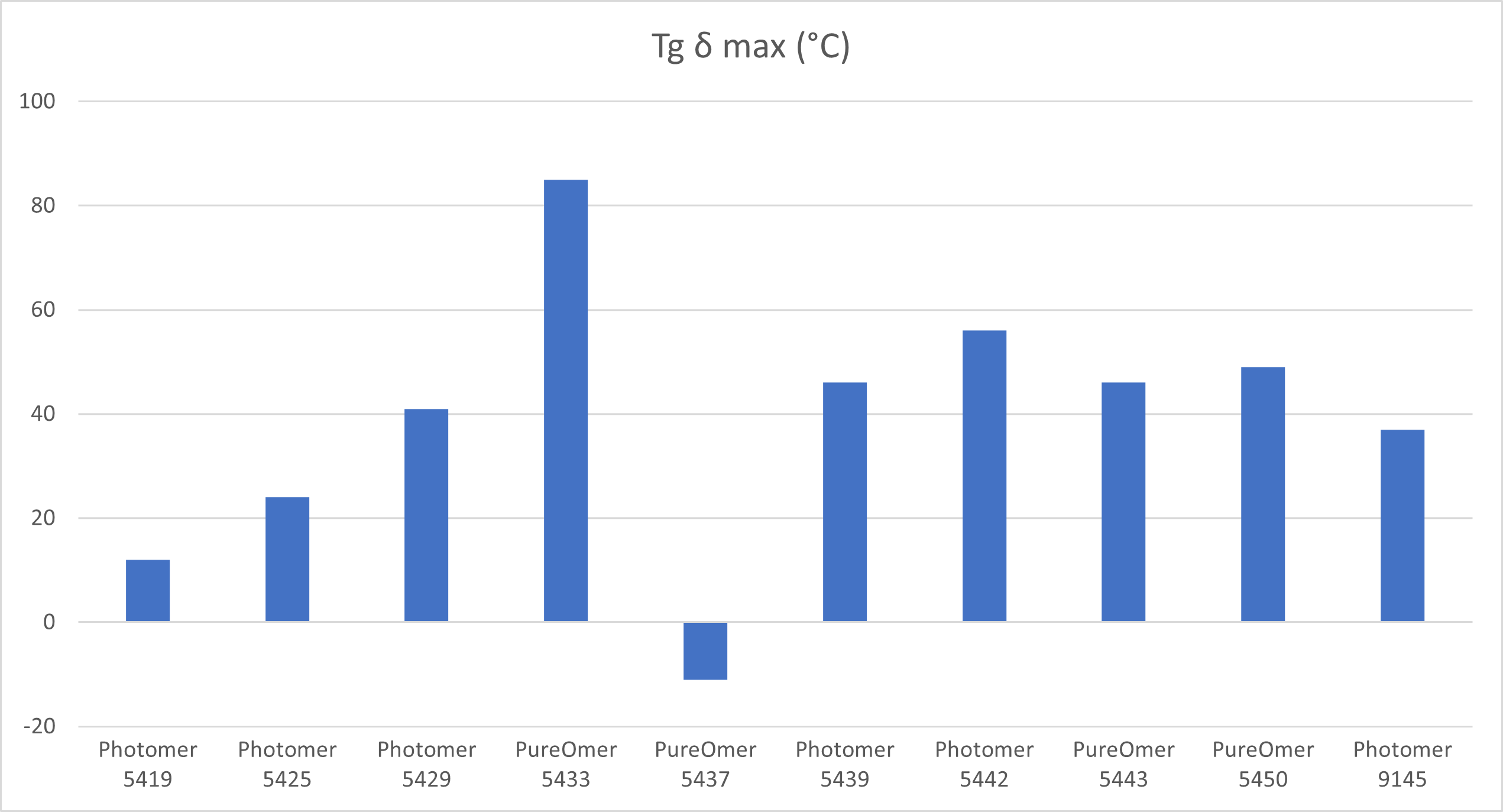

Dynamic Mechanical Analysis (DMA) on a Discovery DMA 850 instrument was used to determine glass transition properties. Specimens were clamped in tensile mode, cooled to -60°C, and heated to 200°C at a rate of 2°C/min. Tg values were derived from the storage modulus onset and the maximum tan delta value.

PureOmer® 5433 recorded the highest Tg (85°C), while PureOmer® 5437 showed the lowest (-11°C), indicating a wide range of thermal stability.

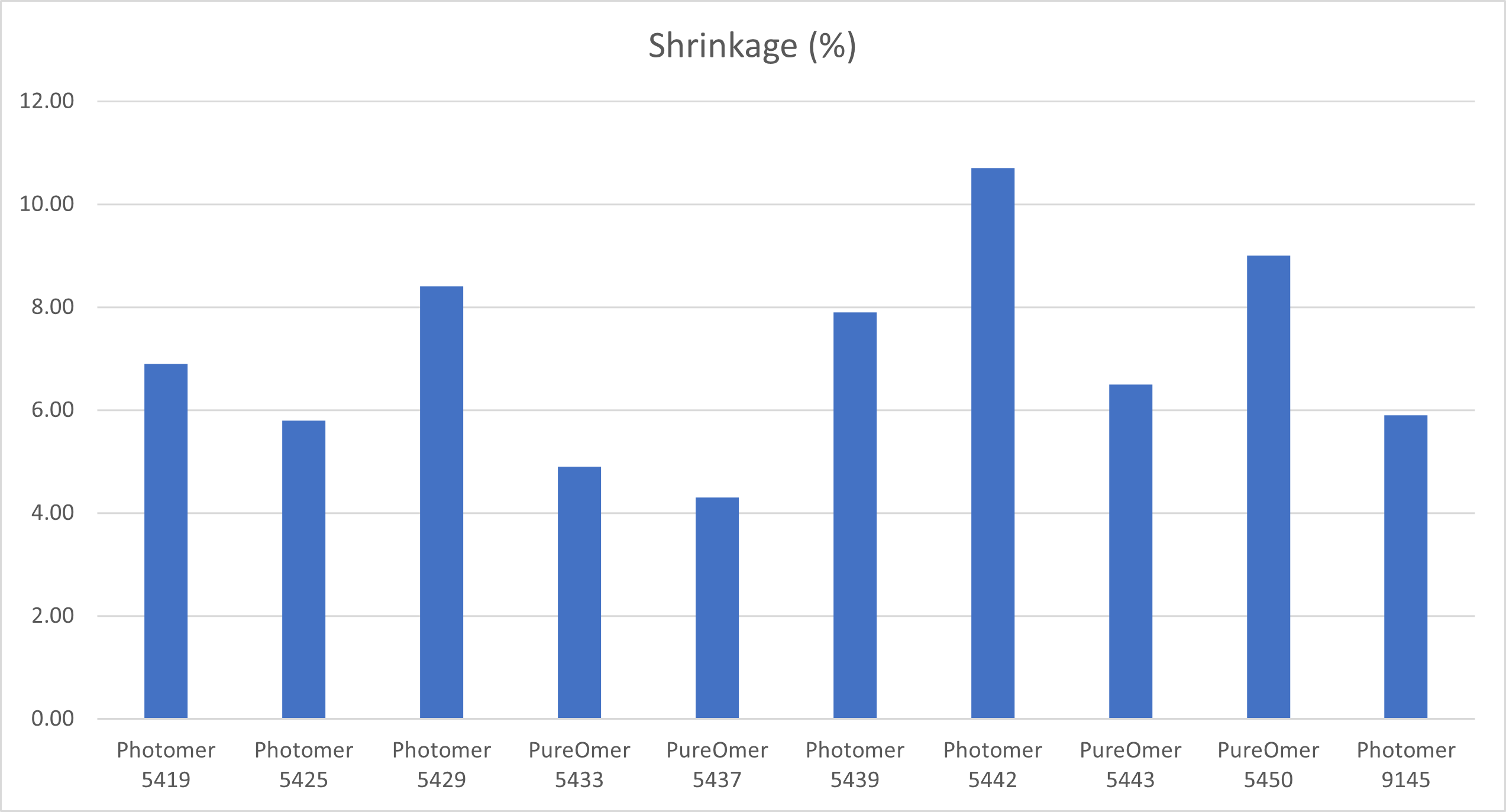

Volumetric Shrinkage

PureOmer® 5437 exhibited the lowest shrinkage (4.3%), making it highly suitable for applications requiring dimensional stability. Similarly, PureOmer® 5433 achieved low shrinkage (4.9%), further supporting its use in precision-demanding applications.

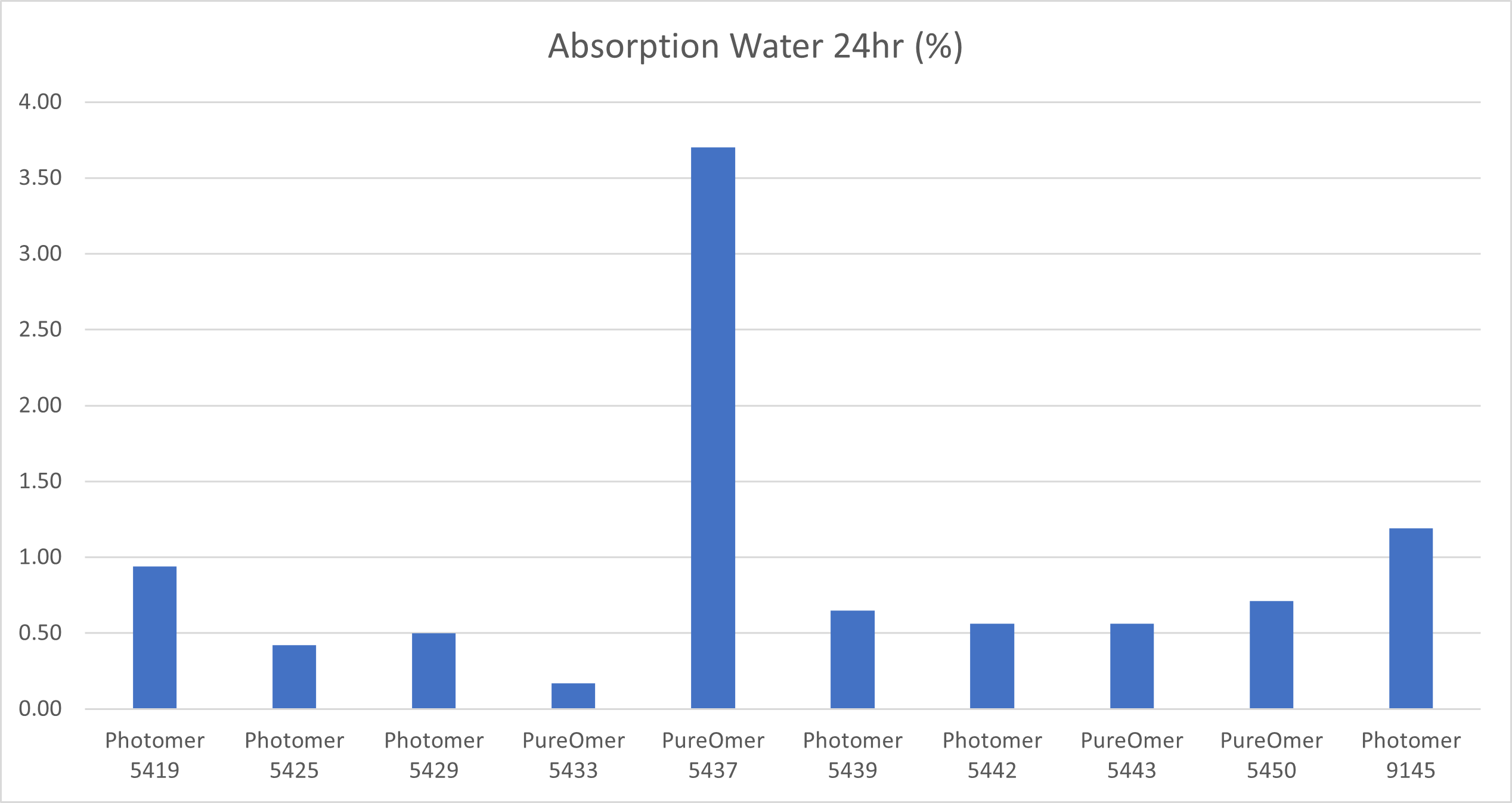

Water Absorption

PureOmer® 5433 had the lowest water absorption (0.17%), making it ideal for use in moisture-sensitive environments.

Shore Hardness

Test specimens for Shore Hardness were prepared using a 2-inch aluminum pan cured with a 395 nm LED light source and further treated with an Hg lamp.

Measurements ranged from D58 for Photomer® 5419 to D91 for PureOmer® 5450, reflecting a spectrum of surface durability and rigidity.

Polyester Acrylate Ranking

The tested polyester acrylates can be categorized into three main groups based on their mechanical and thermal properties:

- Hard: PureOmer® 5433, Photomer® 5442, PureOmer® 5450, Photomer® 5439. These products demonstrated high tensile modulus, strength, and Shore Hardness, making them ideal for applications requiring durability and rigidity.

- Intermediate: PureOmer® 5443, Photomer® 5429, Photomer® 9145, Photomer® 5425. These materials provided balanced performance, suitable for versatile industrial applications with moderate mechanical demands.

- Soft: Photomer® 5419, PureOmer® 5437. These acrylates showed higher elongation at break and flexibility, making them excellent for soft or impact-resistant coatings and adhesives.

This categorization highlights the versatility of polyester acrylates in addressing specific application requirements across various industries.

Key Insights for Ink and Coating Formulators

These findings underscore the diverse mechanical and thermal properties of polyester acrylates, catering to a wide range of industrial applications. Among the tested products, PureOmer® 5433 stood out for its exceptional tensile strength and modulus, and combined low shrinkage and water absorption with excellent dimensional stability. On the other hand, Photomer® 5442’s higher shrinkage rate positions it for specialized applications where rigidity is advantageous.

Conclusion

The comprehensive characterization of polyester acrylates enhances their global promotion and application. By meeting the unique demands of industrial coatings, adhesives, and 3D printing, iGM Resins remains at the forefront of innovation in energy-curing materials, delivering customized and reliable solutions for modern industries.

Want to know more about this study and gain deeper insights? Contact us today to explore tailored solutions and elevate your products to new heights.