OUR products

Energy Curing Resins

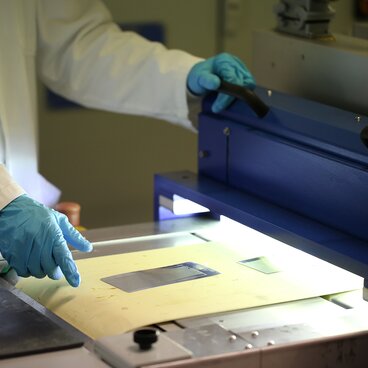

Our Photomer® product range offers customers worldwide a full range of monomers, oligomers and specialties. Our portfolio covers all UV/EB curing markets and includes products that meet specific end-use requirements such as sensitive packaging and high renewable content acrylates.

photoinitiators

Selection of the appropriate photoinitiator is key in achieving the desired balance between cure speed and performance properties of the formulated system after UV cure. The optimal choice depends on the resin systems, UV source, substrate and other requirements. With our global manufacturing footprint, broad range of photoinitiators including new innovations and our technical and application experience, IGM is best positioned to support customer needs in all markets.Our photoinitiators are available under the brand names Omnirad®, Omnipol®, Omnicat® and Esacure®.

additives

IGM Resins supplies a full range of complimentary non acrylate oligomers, fillers and additives that mostly do not participate in the polymerization reaction and remain embedded in the cured network such as UV absorbers, inhibitors, antioxidants and stabilizers for your formulation needs.